Rhodium and its Alternatives

Rhodium and its Alternatives

In the world of electroplating, rhodium is often referred to as the king of precious metals due to its unique properties and breathtaking shine.

Rhodium is one of the rarest (precious) metals in the world. As a by-product of platinum mining, only around 25 tons are produced worldwide each year, in an industrially complex process. The properties of this precious metal explain its popularity: its precious shine provides excellent protection against unwanted discoloration and tarnishing effects. In addition, plated rhodium is very abrasion-resistant and is characterized by its high whiteness and brightness.

Rhodium price still at a high level

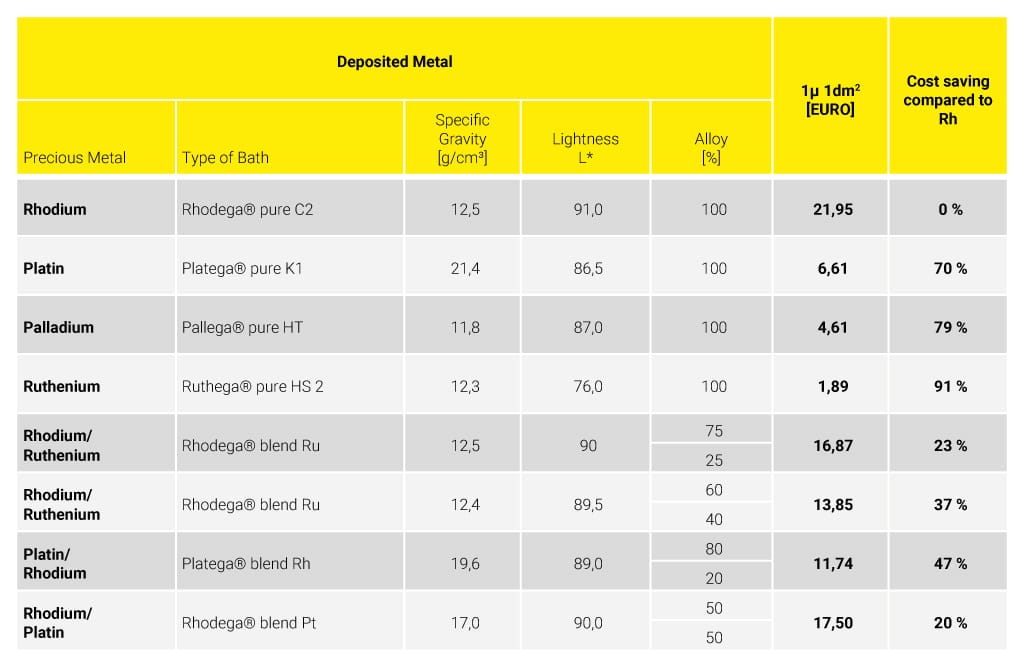

The price of rhodium has climbed to dizzying heights in recent years and is currently still at a high level. There is still more than enough demand for alternatives. One promising option is the use of alloys that combine rhodium with other metals, such as ruthenium or platinum. These alloys offer similar aesthetic and functional properties to pure rhodium, but at a lower price and with wider availability.

Rhodium-Ruthenium alloys from IWG

The combination of rhodium and ruthenium has proven to be extremely successful. This alloy can not only deliver the desired aesthetic characteristics, but also excellent hardness, corrosion resistance and tarnish protection, making it ideal for applications in the jewelry industry, electronics, automotive and many other sectors. In addition, it enables precise control of coating thickness and composition, leading to consistent and high-quality results.

By using rhodium-ruthenium electrolytes such as Rhodega® blend Ru, companies can not only reduce the cost of their plating processes, but also reduce their environmental impact. These electrolytes often require lower operating temperatures and lower amounts of chemicals compared to other plating methods, resulting in an overall more sustainable production.

Rhodium-Platinum alloys from IWG

Another promising alternative is the use of rhodium-platinum alloys. These combine the excellent properties of both metals: The outstanding resistance to corrosion and tarnishing and the shine of rhodium with the exceptional electrical conductivity of platinum.

Rhodium-platinum coatings such as Rhodega® blend Pt or Platega® blend Rh are versatile and are used in areas such as electronics, the automotive industry, medical technology and many others. They not only offer excellent aesthetics and resistance to corrosion, but also high hardness and abrasion resistance, making them ideal for demanding applications.

We have developed solutions for decorative and technical applications that require hardly any compromises in terms of quality and appearance. On the contrary, in our innovation processes we have even succeeded in improving properties such as abrasion resistance in our newly developed Platega® blend Rh: Brilliant white coatings that can stand comparison with pure rhodium and a comparable whiteness. And all this with a significant reduction in precious metal costs.

Electroplating has always been open to new possibilities and alternative materials in order to meet the ever-increasing demands and challenges. By focusing on innovative solutions, we can not only reduce costs, but also improve the sustainability of our processes.